CERTIFIED AS COMPLIANT WITH ISO 9001:2015

Innovative Solutions for Every Job

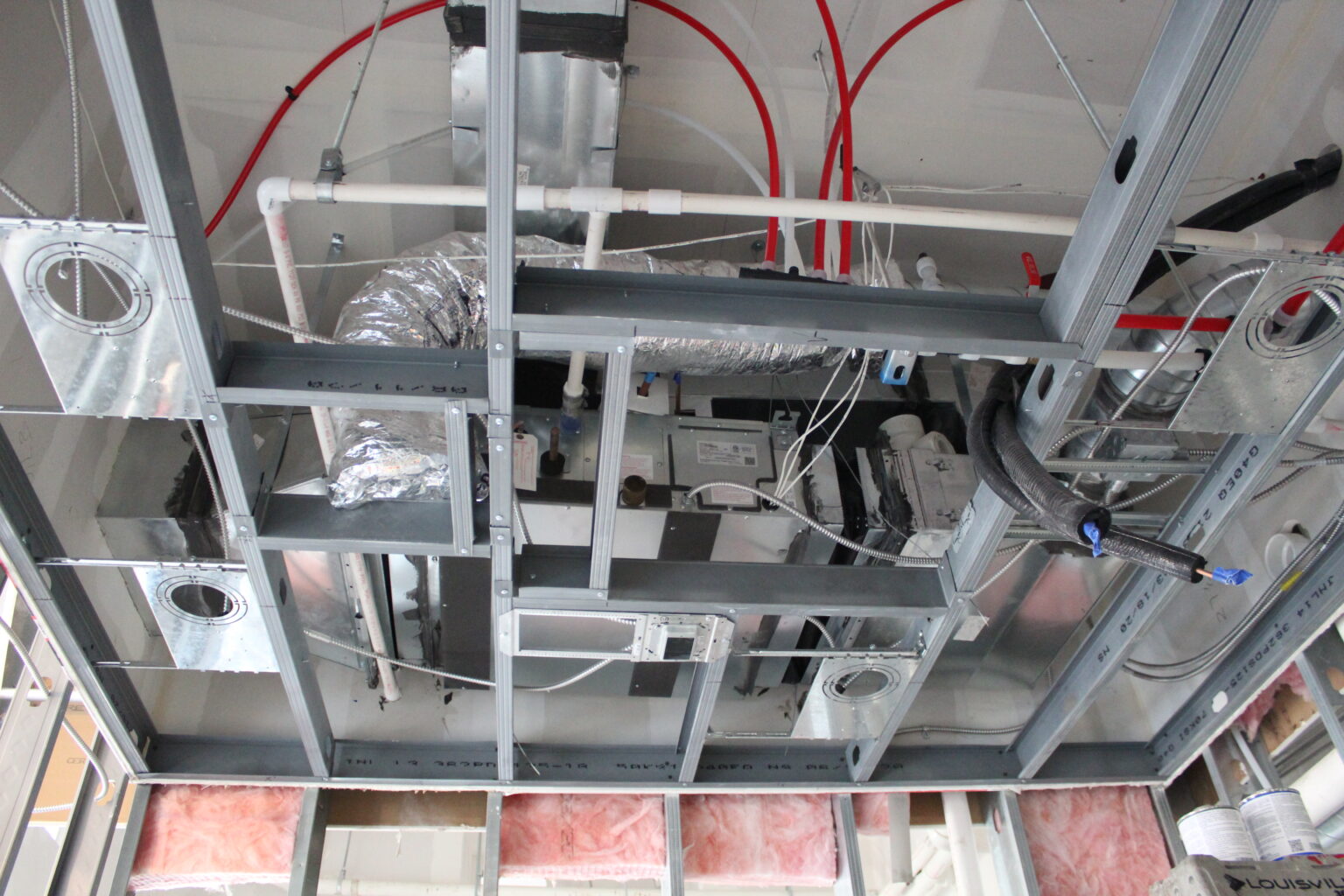

For 40 years TP has been on the cutting edge of fabrication solutions. As early adopters of fabrication techniques, we have mastered the practice and discipline. Our team performs approximately 25% per project man-hours in our fabrication facilities, enhancing schedule, safety and on-site labor.

Our decades of fabrication experience have laid a foundation for our design and engineering teams to creatively adapt and problem solve, leading the industry in fabrication through innovation. TP continues to invest in the latest technology and resources to bring multiple systems together, assemble large components, build full mechanical rooms and deliver them on-site, ready for installation.

Capabilities

Design

Fabricate

Assemble

Deliver

Install

Systems

- Boiler Skids

- Pump Skids

- Pump Headers

- Chemical Treatment Stands

- Pipe & Duct Racking Assemblies

- Air Compressor Skids

- Fully Assembled Mechanical Rooms

- Mixing Valves

- Plumbing Fixtures

- Water Heater Skids

- Medical Gas Headwalls

- Trench Drains

- Roof Drain Assemblies

- Acid Neutralization Tanks

- Restroom Carrier Groups

- Backflow Preventers

- Pressure Reducing Stations

- Medical Gas Equipment Skids

- Wet Wall Assembly

- Assembly of VAV Boxes

- Assembly of Duct Work

- Risers and Run Outs

- Condensing Units on Stands and Pre-piped

- Heat Pumps

- Multi-Trade Racks

- Wet Systems

- Dry Systems

- Fire Pump Systems

- Pre-Action Systems

- Standpipe Systems

- Antifreeze Systems

DESIGN TO INSTALLATION

A Commitment to Quality-Driven Processes

Our Cincinnati fab shop was one of the first shops in the Midwest to be certified as Compliant with the ISO 9001:2015 Standard for Quality Management Systems. TP was specially recognized for “fabrication of components for the purpose of fast-track construction in the piping and mechanical plumbing fields.”

WHY FABRICATION?

Safety, Precision, Productivity

- Reduction in job site waste & debris

- Ensure pricing accuracy to help you stay within budget

- Enhance quality and consistency with specialized work groups

- Ensure local code compliance with pretested systems before delivery

- Shorten construction timelines: 4 – 6 weeks ahead of job site needs

- Eliminate delays due to inclement weather and schedule conflicts

DISTRIBUTION CAPABILITIES

Keeping Your Project on Schedule

Our distribution centers are a large piece of our streamlined project delivery method. We can order and secure longer-lead-time materials, store them in our facilities and deliver them to a job site as needed – enabling us to ensure hard-to-procure materials do not delay the project schedule. We also verify all materials, components and assemblies are accurate before delivery to a job site to avoid installation delays. These differentiators provide TP Mechanical with the flexibility to adjust to ever-changing project demands and to complete your project on time.