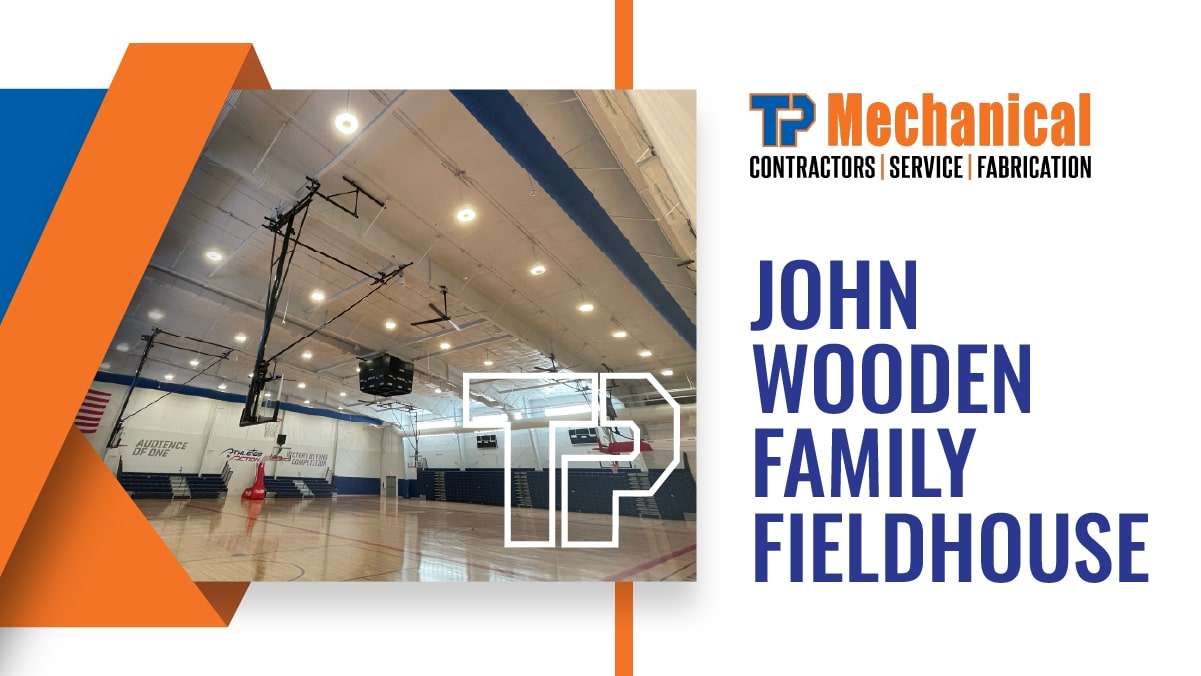

At TP Mechanical, every project we undertake is an opportunity to blend innovation, precision and community impact. Our recent work on the John Wooden Field House in Xenia, Ohio, exemplifies this commitment. This state-of-the-art facility, named after the legendary UCLA coach, was developed for Athletes in Action, a nonprofit dedicated to nurturing athletes into Christ-centered leaders. We’re proud to have played a key role in bringing this vision to life.

A Facility That Inspires

The John Wooden Field House is the only building outside Los Angeles to bear Coach Wooden’s name. The campus spans 250 acres and includes synthetic turf fields, a 275-bed retreat center, a chapel, a challenge course and conference spaces. Athletes nationwide now have access to a premier facility to train and develop physically, mentally, and spiritually.

Our Systems

As the HVAC and plumbing contractor, TP Mechanical managed:

- Installation of four rooftop HVAC units

- Fabrication and installation of 13-bathroom carrier group systems

- High-elevation ductwork for the gymnasium

- Underground and above-ground sanitary and storm piping

- Domestic water and chilled water systems

- Ductwork, VAVs, and process piping

We closely coordinated with Corna Kokosing Construction, the general contractor, and experienced smooth, productive collaboration throughout the project lifecycle.

Quality, Technology, and Timely Execution

Our Quality Control Manager conducted bi-monthly site visits to uphold our high standards. Simultaneously, Superintendent Scott Ashford and Project Manager Josh Bolton led weekly walk-throughs to ensure the work met our functional and aesthetic benchmarks.

In modern buildings, exposed mechanical systems are often part of the visual design. We ensured that every pipe and duct was functional and installed with visual precision—straight, level, and cleanly aligned.

We also leveraged Trimble technology to achieve precise layout and alignment of underground utilities and hangers. Our team responded quickly and efficiently when a minor layout issue arose, resolving it with minimal rework thanks to strong coordination and communication.

Despite early weather-related delays and challenges with equipment lead times, the project stayed on track and was even completed ahead of schedule. Final testing and turnover were smooth and successful, reinforcing our commitment to excellence at every step.