Every sophisticated machine has thousands of moving parts that come together to make a whole, working system.

A car, for example, is made up of an electrical system, an engine, a computer system, a transmission and systems for steering and suspension, to name a few. Each of these systems is comprised of complex parts and intricate details. Built separately and standing alone, they work flawlessly.

However, a car does not function unless each of these systems can be connected and integrated without error. The systems cannot be designed in isolation. They must be engineered to ensure that their pieces connect and work together.

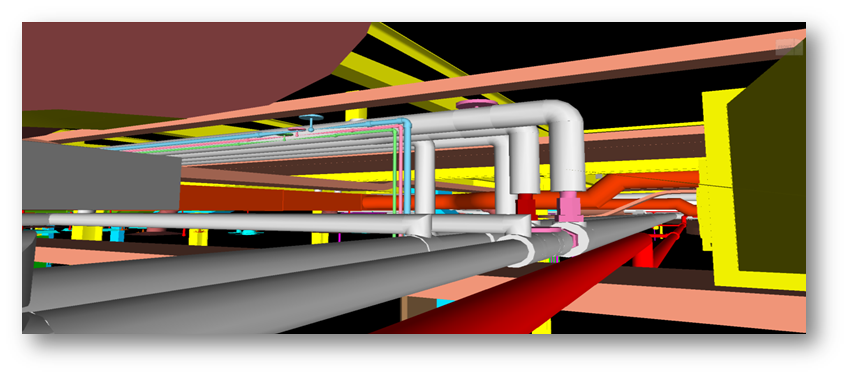

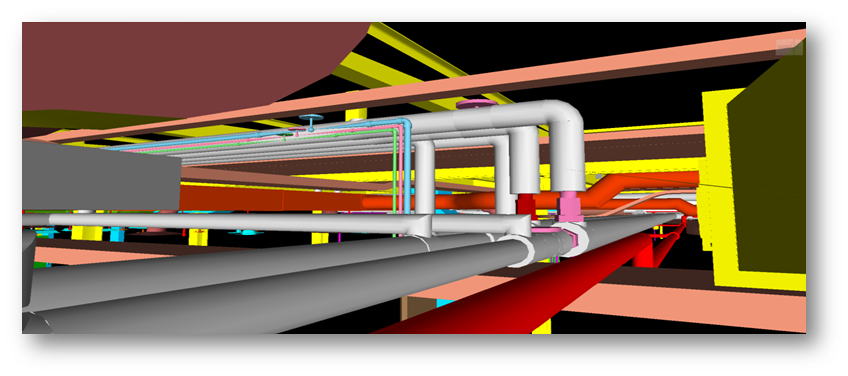

A building is like a car. Behind the walls, many sophisticated systems are humming along individually and have been engineered to function cohesively. The plumbing has to fit around the HVAC system; the electrical lines have to be accessible; water and electricity must flow seamlessly and control units must be easy to get to. All of these pieces have to fit behind the walls, among the building’s framework, beneath floors and above ceilings.

BIM (Building Information Modeling) makes all of this easier to design, manage and install. By allowing designers and engineers to create and integrate designs in a virtual 3-D environment, multiple trades can collaborate on one project, share designs digitally and virtually envision how the systems will combine within the space and coexist.

The benefits of this technology are numerous:

- Multiple trades collaborate on comprehensive projects before the first pipe is welded, allowing for seamless integration of multiple systems and eliminating confusion on the jobsite at installation time.

- The level of detail that we can design allows us to carefully plan for every contingency, eliminate waste, reduce time on the jobsite and cut costs associated with expensive errors and revisions.

- New or upgraded systems can be designed and incorporated into existing buildings or blueprints with ease.

- Custom parts can be designed to solve complex challenges that arise on a project.

- Sophisticated custom systems such as corridor racks, medical gas walls, pump skids, water heater packages, pipe racks and underground systems can be designed and fabricated in the controlled environment of a manufacturing facility.

At one time in the construction business, each of these systems was designed, manufactured and installed separately. Engineers designed systems using paper blueprints and conceptualized the integration of their system with others in their minds’ eye using careful calculation. To visualize how it would all fit together in final layout, other system design blueprints were printed on tracing paper and layered over one another.

When it came time to install and integrate the systems, the job site was clogged with tradesmen, confusion was typical, and errors arose – all causing time-consuming and expensive delays.

Thankfully, the technological advancement of BIM has made these headaches a thing of the past.

Thankfully, the technological advancement of BIM has made these headaches a thing of the past.

The applications of BIM technology are exponentially versatile. The TP Mechanical design/build team has extensive expertise utilizing BIM to the benefit of all of our clients and has solved the toughest of challenges by optimizing little-known BIM capabilities.

Ultimately, BIM technology is invaluable to us as we strive to save our clients time and money. It’s a crucial tool that allows TP Mechanical to deliver innovative solutions and speed projects to completion. In short, BIM is the glue that makes a project’s multiple moving parts – trades, timelines, systems and budgets – come together faultlessly.